Sulphuric Acid

SULPHURIC ACID, or OIL OF VITRIOL, H 2 S0 4 , perhaps the most important of all chemicals, both on account of the large quantities made in all industrial countries and of the multifarious uses to which it is put. It is not found in nature in the free state to any extent, and although enormous quantities of its salts, especially calcium and barium sulphate, are found in many localities, the free acid is never prepared from these salts, as it is more easily obtainable in another way, viz. by burning sulphur or a sulphide, and combining the sulphur dioxide thus formed with more oxygen (and water).

Originally prepared by heating alum, green vitriol and other sulphates, and condensing the products of distillation, sulphuric acid, or at least an impure substance containing more or less sulphur trioxide dissolved in water, received considerable attention at the hands of the alchemists. The acid so obtained from ferrous sulphate (green vitriol) fumes strongly in moist air, hence its name " fuming sulphuric acid "; another name for the same product is " Nordhausen sulphuric acid," on account of the long-continued practice of this process at Nordhausen.

Ordinary sulphuric acid, H 2 SO4, may be prepared by dissolving sulphur trioxide in water, a reaction accompanied by a great evolution of heat; by the gradual oxidation of an aqueous solution of sulphur dioxide, a fact which probably explains the frequent occurrence of sulphuric acid in the natural waters rising in volcanic districts; or by deflagrating a mixture of sulphur and nitre in large glass bells or jars, absorbing the vapours in water and concentrating the solution. The latter process, which was known to Basil Valentine, was commercially applied by the quack doctor, Joshua Ward (1685-1761), of Twickenham, England, to the manufacture of the acid, which was known as " oil of vitriol made by the bell " or per campanum. Dr John Roebuck (1718-1794), of Birmingham, replaced the glass vessels by leaden ones, thereby laying the foundation of the modern method of manufacture (see below).

Properties. Pure sulphuric acid, H 2 SO4, is a colourless, odourless liquid of an oily consistency, and having a specific gravity of 1-8384 at 15. It boils at 338, and at about 400 the vapour dissociates into sulphur trioxide and water; at a red heat further decomposition ensues, the sulphur trioxide dissociating into the dioxide and water. It freezes to a colourless crystalline mass, melting at 10-5. The acid is extremely hygroscopic, absorbing moisture from the atmosphere with great rapidity; hence it finds considerable application as a desiccating agent. The behaviour of aqueous solutions of sulphuric acid is very interesting. The pure acid (100% HjSO^ cannot be prepared by boiling down a weaker acid under any pressure (at least between 3 and 300 centimetres of mercury), an acid of the composition H 2 SO 4 , 1 1 jH 2 O or 12SO 3 ,13H 2 O being invariably obtained. Neither is there any advantage gained by mixing this hydrate with sulphur trioxide; for when such a mixture is concentrated by evaporation, sulphur trioxide is vaporized until the same hydrate is left. The pure acid, however, may be obtained by strongly cooling this hydrate.

when it separates in the form of white crystals, which melt at 10-5, and on gentle heating evolve sulphur trioxide and again form the same hydrate. When strong sulphuric acid is mixed with water there is a great development of heat; the heat evolved when four parts of acid are mixed with one of water being sufficient to raise the temperature from o to 100 C. (Hence the laboratory precaution of always adding the acid to the water and not the water to the acid.) In addition to the heat evolution there is also a diminution in volume, the maximum occurring when the components are present in the ratio H 2 SO4:2H 2 O, thus pointing to the existence of a hydrate H 2 SO 4 ,2H 2 O. A second hydrate, H 2 SO 4 ,H 2 O, may be obtained as rhombic crystals, which melt at 7 and boil at 205, by diluting the strong acid until it has a specific gravity of 1-78, and cooling the mixture; this compound is sometimes known as glacial sulphuric acid. Both the mono- and di-hydrates form freeing mixtures with snow. Other hydrates have also been described.

Reactions. Sulphuric acid has the widest commercial application of all chemical reagents. Here only reactions of commercial utility will be considered, and reference should be made to the article SULPHUR for reactions which are more of a purely scientific interest. In inorganic chemistry its principal applications are based on its solvent power for metals, and its power of expelling other acids from their salts. In the first group we have to notice the use of iron or zinc and dilutesulphuric acid for the manufacture of hydrogen, which may be used directly, as for inflating balloons or for purposes of combustion, or in the nascent condition, for reduction purposes, as generally is the case in organic chemistry (see ANILINE). It is worthy of notice that while many metals dissolve in cold dilute sulphuric acid, with the liberation of hydrogen, in accordance with the typical equation: M + H 2 SO4 = MSO 4 + H 2 (M denoting one atom of divalent or two atoms of a monovalent metal), there are several (copper, mercury, antimony, tin, lead and silver) which are insoluble in the cold dilute acid, but dissolve in the hot strong acid with evolution of sulphur dioxide, thus: M + 2Hj2SO 4 = MSO 4 + SO + 2H 2 O. Carbon decomposes hot strong sulphuric acid on long continued boiling, with the formation of carbon dioxide and sulphur dioxide. The power which sulphuric acid exhibits for expelling other acids from their combinations, a power occasioned by its comparative involatility and high degree of avidity, forms the basis of a considerable number of commercial processes. Hydrochloric, hydrobromic, hydriodic, hydrofluoric, nitric, phosphoric and many other acids are manufactured by the action of sulphuric acid on their salts; the alkali and chlorine industries, and also the manufacture of bromine and iodine, employ immense quantities of this acid.

In organic chemistry sulphuric acid is extensively employed. Its powerful affinity for the elements of water makes it a valuable dehydrating and condensation agent. It extracts the elements of water from formic acid, giving carbon monoxide; from oxalic acid, giving a mixture of carbon monoxide and dioxide; from alcohol, to give ether or ethylene according to the conditions of the experiment ; and from many oxygenated compounds (e.g. sugar, tartaric acid, etc.), with the production of charred masses. The formation of esters and ethers are generally facilitated by the presence of this acid. It also acts in an opposite manner in certain cases, adding the elements of water to compounds; thus, nitriles are converted into acid-amides, and various acetylene derivatives may be caused to yield ketonic derivatives. As an oxidizing agent its application is limited. The transformation of piperidine into pyridine by W. Konigs, and the observation that anthraquinone yielded oxyanthraquinones when treated in the cold with strong sulphuric acid, and the recent introduction of fuming sulphuric acid for the oxidation of naphthalene to phthalic acid, a process of great value in the manufacture of artificial indigo, may be noted. But its chief technical application depends upon the formation of sulphonic acids when it reacts with aromatic hydrocarbon residues; these compounds being important either as a step towards the preparation of hydroxy-compounds, e.g. resorcin, the naphthols, alizarin, etc., or for preparing dye-stuffs in a more soluble form.

Sulphates. Sulphuric acid, being a dibasic acid, forms two series of salts with monovalent metals: an acid sulphate, MHSO 4 , and a normal sulphate, MSO 4 . Acid sodium sulphate, NaHSO 4 , has been employed in the manufacture of sulphur trioxide. When heated it loses water to form sodium pyrosulphate, Na^O?, which on treatment with sulphuric acid yields normal sodium sulphate and sulphur trioxide. The normal sulphates are the more important, and occur widely and abundantly distributed in the mineral kingdom; anhydrite, gypsum, anglesite, barytes, celestite and kieserite are among .the commonest species. As a general class, the sulphates are soluble in water, and exhibit well crystallized forms. Of the most insoluble we may notice the salts of the metals of the alkaline earths, barium, strontium and calcium, barium sulphate being practically insoluble, and calcium sulphate sparingly but quite appreciably soluble. Lead sulphate is very slightly soluble in water, soluble in strong sulphuric acid, and almost insoluble in alcohol.

Sulphates may be detected by heating the salt mixed with sodium carbonate on charcoal in the reducing flame of the blowpipe; sodium sulphide is thus formed, and may be identified by the black stain produced if the mass be transferred to a silver coin and then moistened. In solution, sulphates are always detected and estimated by the formation of a white precipitate of barium sulphate, insoluble in water and all the common reagents.

Manufacture. The first step in its manufacture is the combustion of sulphur. Formerly this was employed exclusively in the free state as brimstone, and this is still the case to a considerable extent in some countries, notably in the United States, but the great bulk of sulphuric acid is now made from metallic sulphides, especially those of iron and zinc. Most of the brimstone of trade comes from Sicily, but in the United States Louisiana sulphur is playing an important part, and seems likely to oust the Sicilian sulphur. Free sulphur is also contained as " gas sulphur " in the " spent oxides " of gasworks, which are actually utilized for the manufacture of sulphuric acid. Sulphur is also recovered in a very pure state from the " alkali waste " of the Leblanc process, but this " recovered sulphur " is too expensive to be burned for the purpose in question. In the United Kingdom much gas sulphur is used for the manufacture of sulphuric acid, together with a limited quantity of Sicilian sulphur for the production of sulphuric acid free from arsenic.

A much larger percentage of the sulphuric acid is made from pyrites, i.e. more or less pure disulphide of iron which occurs in large quantities in many countries. Great Britain produces very little of it, Ireland a little more, but of poor quality. Most of the pyrites consumed in the United Kingdom come from Spain; this Spanish pyrites generally (not always) contains enough copper (say 3 or 4%) to make its extraction from the residues (" cinders ") a paying process, and this of course cheapens the price of the sulphur to the acid manufacturer. Spain also supplies much pyrites to Germany, France and America, all of which countries are themselves producers of this ore. Sweden and Norway are exporters of it to all these countries. Good pyrites contains from 48 to 50 %, exceptionajly up to 52 % of sulphur, of which all but from I to 4% is utilized when burning the ore. Another metallic sulphide, blende, ZnS, is of importance for Germany, Belgium and the United States, much less so for the United Kingdom, as a source of sulphur. Blende contains only about half as much sulphur as good pyrites, and this cannot be burned off as easily as from pyrites, but this " roasting " has to be done somehow in any case in order to prepare the ore for the extraction of the zinc.

Brimstone is easily burned without any extraneous help; indeed the only precaution required is to take care lest the heat produced by the burning sulphur should not volatilize part of it in the unburned state. This can never be entirely avoided, and sometimes causes trouble in the succeeding apparatus.

The roasting of pyrites always takes place without using any extraneous fuel, the heat given off by the oxidation of the sulphur and the iron being quite sufficient to carry on the process. If the ore is in pieces of the size of a walnut or upwards, it is roasted in plain " kilns " or " burners," provided with a grating of suitable construction for the removal of the cinders, with a side door in the upper part for charging in the fresh ore on the top of the partially burned ore, and with an arch-shaped roof, from which the burnergas is carried away in a flue common to a whole set of kilns. The latter are always set in a row of twelve or more, and are one after another charged once or twice a day at appropriate intervals, so that a regular evolution of gas takes place all the day round. By employing suitable precautions, a gas of approximately uniform composition is obtained, containing from 6 to 8 % sulphur dioxide, SO 2 , with a little trioxide, SOa, and about 12% of oxygen, which is more than sufficient for converting later all the SO 2 into SO> or HjSO 4 . The burning of " smalls " or " dust " was formerly considered much more difficult and incomplete than that of pieces, but this ( difficulty has been entirely overcome in various ways, principally by the " shelf-burner," originally constructed by E. Maletra, and mechanical burners, which were formerly almost entirely confined to America, where the saving of labour is a primary consideration. The first really successful mechanical pyrites-burner was constructed many years ago by MacDougall Bros, of Liverpool. The drawbacks still present in this burner caused it to be abandoned after a few years, but they have since been overcome by several recent inventors, principally American. The Hereshoff burner has been most widejy introduced, both in America and in European countries. The roasting of blende is nothing like so easy as that of pyrites, since the heat developed by the oxidation of the zinc sulphide itself is not sufficient for carrying on the process, and external heat must be applied. It is now usually performed by a series of muffles, superposed one over another, so that the whole forms a kind of shelfburner, with internally heated shelves (the " Rhenania " furnace). This operation is both more costly and more delicate than the roasting of pyrites, but it is now perfectly well understood, and gas is obtained from blende furnaces hardly inferior in quality to that also inde.

13 wuuuQU ii<Jiii uiciiuc luiiiai-ca udiuiy iiuciiui in ljuaiiiy LU i yielded by pyrites kilns. In America, and quite exceptionally < in Europe, mechanical furnaces are used for the roasting of bier The gas produced in the burning of sulphur ores, when issuing from the burner, holds in mechanical suspension a considerable quantity of " flue-dust," which must be removed as far as is practicable before the gas is subjected to further treatment. Flue-dust contains principally ferric oxide, zinc oxide, arsenious and sulphuric acids, and small quantities of the various metals occurring in the raw ore. All the thallium and selenium on the market is obtained from this source. Sometimes the burner-gas is employed directly for the sake of the SO 8 which it contains, principally in the manufacture of " sulphite cellulose " from wood. When the gas is to be utilized for the manufacture of sulphuric acid the SO 2 must be combined with more oxygen, for which purpose an " oxygen carrier " must be employed. Until recently the only agent practically used for this purpose was furnished by the oxides of nitrogen; more recently other oxygen carriers, acting by " contact processes," have also come into use (see below).

The production of sulphuric acid by the assistance of the oxides of the nitrogen is carried out in the " vitriol chambers." These are immense receptacles, mostly from 100 to 200 ft. long, 20 to 30 ft. wide, and 15 to 25 ft. high, constructed of sheet-lead, the joints of the sheets being made by " burning " or autogenous soldering, i.e. fusing them together by a blow-pipe without the aid of spider (which would be quickly destroyed by the acid). The vitriol chambers must be supported on all sides by suitable wooden or iron framework, and they are always erected at a certain height over the ground, so that any leaks occurring can be easily detected. In nearly all cases several of these chambers are connected so as to form a set of a cubic capacity of from 100,000 to 200,000 cub. ft. The burner gas is introduced at one end, the waste gases issue from the other, the movement of the gases being impelled partly by their own chemical reactions, partly by the draught produced by a chimney (or tower), or by mechanical means. At the same time water is introduced in a number of places in the shape of steam or finely divided as a spray, to furnish the material for the reaction : SOi + O + HjO = HjSCh. As this reaction of its own accord takes place only to a very small extent, an " oxygen carrier " is always introduced in the shape of the vapours of nitric acid or the lower oxides of nitrogen. By the play of reactions induced in this way practically the whole of the SO 2 is ultimately converted into sulphuric acid, and at the same time the nitrogen oxides are always recovered with comparatively very slight losses and made to serve over again.

The reactions taking place in the vitriol chambers are very complicated, and have been explained in many different ways. The view hitherto accepted by most chemists is that developed by G. Lunge, according to which there are two principal reactions succeeding each other, it may be in quite contiguous places, but under different conditions. Where the nitrous fumes prevail and there is less water present, sulphur dioxide combines with nitrous icid and oxygen to form nitroso-sulphuric acid, a crystalline subtance of the formula SO 2 (OH)(ONO). The reaction is therefore: ">. + O + HNO, = SO 6 NH. The solid substance is, however, _.Jy exceptionally met with, as it at once dissolves in the mist of sulphuric acid floating in the chamber and forms " nitrous vitriol." Wherever this nitrous vitriol comes into contact with liquid water (not steam), which is also present in the chamber in the shape of mist, and practically as dilute sulphuric acid, it is decomposed into sulphuric and nitrous acid, thus: SO 2 (OH)(ONO) + HjO = HSC>4 + HNO2. The re-formed nitrous acid, although not stable, any more than is its anhydride, N 2 O 3 , is nevertheless the " oxygen carrier " in question, as the products of its spontaneous decomposition, when meeting with other compounds, always react like nitrous acid itself and thus may transfer an indefinite quantity of oxygen to the corresponding quantities of SOj and HjO, with the corresponding formation of H 2 SO4. This theory at once explains, among other things, why the acid formed in the vitriol chambers always contains an excess of water (the second of the above-quoted reactions requiring the " mass action " of this excess), and why the external cooling produced by the contact of the chamber sides with the air is of great importance (liquid water in the shape of a mist of dilute sulphuric acid being necessary for the process).

In 1906 Lunge (in a paper published with Bert) to some extent modified his views, by introducing an intermediate compound, sulphonitronic acid, SOsNHj, which had been noticed by various chemists for some time through its property of imparting a deep blue colour to sulphuric acid. It is evident that the nitrous gases " present in the vitriol chamber consist essentially of a mixture of NO and NO, the latter being formed from NO by the excess of oxygen present. The NO 2 (or NO + O) reacts upon SO 2 + H 2 O, forming SOsNH^ which, being extremely unstable, is at once oxidized to SO^NH (nitroso-sulphuric acid). The latter is now either converted by hydrolysis into sulphuric acid and nitrogen oxides: 2S0 6 NH + H 2 = 2HjSO, + NO + NO 2 , the latter acting as before: or it reacts with more SO 2 , forming again sulphonitronic acid: 2SO 4 NH + SO 2 + 2H 2 O = H 2 SO 4 + 2SO 6 NHj. The latter ,n also split up directly into NO and SO 4 H 2 .

Whatever be the true theory of the vitriol-chamber process, there is no doubt about the way in which the reactions have to be carried out in practice. Since the reactions occur among gases and liquids in the nebulous state, vast spaces have to be provided in which the process may be carried out as completely as possible before the waste gases are allowed to escape into the outer air. These spaces cannot be constructed in any other way than is actually done in the shape of the lead chambers ; neither iron nor brickwork can be employed for this purpose/as they would be quickly destroyed by the acid liquids and gases.

When issuing from the chambers, the gases still contain the whole of the free nitrogen contained in the air which had entered into the burners, together with about a third, or at least a fourth, of the oxygen originally present therein, such excess of oxygen being required in order to carry out the conversion of the sulphur dioxide into sulphuric acid as completely as possible. For similar reasons it is necessary to employ much more water than is required to form H 2 SO4l and this is all the more necessary as strong sulphuric acid dissolves the nitrous compounds in the shape of nitroso-sulphuric acid, and thus withdraws these oxygen carriers from the gas-space of the chambers where the necessary reactions take place. It follows from this that the acid collecting at the bottom of the chambers must never exceed a certain concentration, say 70%, H 2 SO4 having a specific gravity of 1-615, Dut it ' s preferable to make it only 66 to 67%, having a specific gravity of 1-57 to 1-58. On the other hand, it should never go down below 60 % H 2 SO4, equivalent to a specific gravity of 1-50.

The commercial production of sulphuric acid imperatively requires that the nitrogen oxides (which originally were always introduced in the shape of nitric acid) should be available as long as possible, before being lost mechanically or by reduction to the inactive forms of nitrous oxide or elementary nitrogen. The first step towards securing this requirement was taken as early as 1827 by Gay-Lussac, who discovered that the nitrous fumes, otherwise carried away from the lead chambers by the waste atmospheric nitrogen and oxygen, could be retained by bringing the gases into contact with moderately strong sulphuric acid, the result being the formation of nitroso-sulphuric acid: 2H 2 SO4 + N 2 O = 2SO 2 (OH)(ONO) + H 2 O, and the latter remaining dissolved in sulphuric acid as " nitrous vitriol." But this important invention was of little use until John Glover, about 1866, found that the nitrous vitriol could be most easily reintroduced into the process by subjecting it to the action of burner-gas before this enters into the lead chambers, preferably after diluting it with chamber acid, that is, acid of from 65 to 70%, H 2 SO4, as formed in the lead chambers. The reaction is then : 2SO 2 (OH)(ONO) + SO 2 + 2H 2 O = 3H 2 SO4 + 2NO; that is to say, all the "nitre" is returned to the chambers in the shape of NO; the sulphuric acid employed in the Gay-Lussac process is not merely recovered, but an additional quantity is formed from fresh SO 2 ; as the heat of the burner-gases also comes into play, much water is evaporated, which supplies part of the steam required for the working of the chambers; and the acid issues from the apparatus in a " denitrated " and sufficiently concentrated state (78 to 80% H 2 SO4) to be used over again for absorbing nitrous vapours or any other purpose desired. Since that time, in every properly appointed sulphuric acid manufactory, the following cycle of operations is carried out. To begin with, in the burners pyrites (or, as the case may be, brimstone or blende) is made to yield hot burner-gas containing about 7 % (in the case of brimstone 10 or n %) of SO 2 . This, after having been deprived of most of the flue-dust, is passed through the " Glover tower," i.e. an upright cylindrical or square tower, consisting of a leaden shell lined with heat- and acid-proof stone or brick, and loosely filled or " packed " with the same material, over which a mixture of acid from the Gay-Lussac tower and from the chambers trickles down in such proportions that it arrives at the bottom as denitrated acid of from 78 to 80 % H 2 SO4. The gases now pass on to the lead chambers, described above, where they meet with more nitrous vapours, and with steam, or with water, converted into a fine dust or spray. Here the reactions sketched above take place, so that " chamber-acid " as already described is formed, while a mixture of gases escapes containing all the atmospheric nitrogen, some oxygen in excess, about 0-5% of the total SO 2 , and some oxides of nitrogen. This gas is now passed through the Gay-Lussac tower, which somewhat resembles the Glover tower, but is usually filled with coke, over which sulphuric acid of about 80% H 2 SO4 trickles down in sufficient quantity to retain the nitrous vapours. Ultimately the waste gas is drawn off by a chimney, or sometimes by mechanical means.

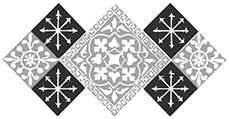

Of course a great many special improvements have been made in the plant and the working of chamber systems; of these we mention only some of the most important. By judiciously watching all stages of the process, by observing the draught, the strength of the acid produced, the temperature, and especially by frequent analyses of the gases, the yield of acid has been brought up to 98% of the theoretical maximum, with a loss of nitre sometimes as low as two parts to 100 of sulphur burned. The supply of the nitric acid required to make up this loss is obtained in England by " potting that is, by decomposing solid nitrate of soda by sulphuric acid in a flue between the pyrites burners and the chambers. On the continent of Europe makers generally prefer to employ liquid nitric acid, which is run through the Glover tower together with the nitrous vitriol. Although this method appears more troublesome, it allows the amount of nitre to be more easily and more accurately regulated. The size of the Glover towers, and more especially that of the Gay-Lussac towers, has been progressively increased, and thereby the cube of the lead chambers themselves has been diminished to a much greater extent. By improved (From Thorpe's Inorg/mk Chemistry.)

Sulphuric Acid Plant.

A, Pyrites burners.

B, Nitre oven.

C, Glover tower.

D, Gay-Lussac tower.

E, Cooling pipes for Glover- tower acid.

F, F, F, Vitriol chambers.

G, Steam boiler.

H, Acid eggs or reservoirs for pumping the acid to top of towers.

I, Steam engine and stonebreaker for breaking up pyrites.

Chimney.

Engine for compressing air.

" packing " the towers have been rendered more durable, and in the case of the Gay-Lussac tower the loss of nitre has been diminished by avoiding the use of a coke packing, which acts upon that substance as a reducing agent. Many attempts have been made to reduce the chamber space by apparatus intended to bring about a better mixture of the gases, and to facilitate the interaction of the misty particles of nitrous vitriol and dilute acid floating in the chamber with each other and with the chamber atmosphere. The earliest really successful, and still the most generally applied apparatus of this kind, is the Lunge-Rohrmann " plate columns " or " reaction towers " placed between the chambers, but though this and similar apparatus has proved to be very useful in the later stages of the process, it has not been found practicable to do away with the lead chambers entirely. The pumping of the acids up to the top of the towers is now always performed by means of compressed air, either in the old "acid eggs," or more economically in " pulsometers."

Most of the sulphuric acid manufactured is not required to be of higher strength than is furnished by the vitriol chambers, either directly (65 to 70%), or after a passage through the Glover tower (78 to 80%). This, for instance, holds good of the acid employed in the manufacture of sulphate of soda and hydrochloric acid from common salt, and in the manufacture of superphosphates. But for many purposes more highly concentrated acid is required. Formerly all such acid was made by boiling down the dilute acid, for which purpose a great variety of apparatus was invented. The first question is always that of material. Lead can be used for the purpose only when the boiling-point of the acid is reduced by means of a vacuum a plan which has not met with much success. Formerly glass vessels were generally employed and they still survive in England, but elsewhere they are not much used. Porcelain, enamelled iron, for high concentrations even cast-iron without any protection, are also in use. On the continent of Europe platinum vessels have been for a long time almost universal, and they have been greatly improved by an internal lining of gold. The second consideration is the form of the vessels; these may be open pans or dishes, or closed retorts, or combinations of both. We also note the Faure and Kessler apparatus, which consists of a platinum pan, surmounted by a double-walled leaden hood, in such a manner that, while the hood is constantly cooled from the outside by water, the thin acid condensing on its inside is carried away without being allowed to flow back into the pan. The majority of acid makers, however, prefer retorts made entirely of platinum, preferably provided by the Heraeus process with a dense, closely adherent coating of gold, including the top or " dome." The new Kessler furnace is a very ingenious apparatus, in which the fire from a gas-producer travels over the sulphuric acid contained in a trough made of Volvic lava, and surmounted by a number of perforated plates, over which fresh acid is constantly running down ; the temperature is kept down by the production of a partial vacuum, which greatly promotes the volatilization of the water, whilst retarding that of the acid. This furnace is also very well adapted for impure acids, unsuitable for platinum or platinum-gold stills on account of the crusts forming at the bottom of the retorts; and it is more and more coming into use both in Great Britain and on the Continent. A third consideration is the condensation of the vapours formed in the concentrating process; the further the concentration proceeds the more sulphuric acid they contain. Condensation is a comparatively easy task in the case of platinum apparatus, but with glass or porcelain beakers or retorts it presents great difficulties. In this respect the Kessler furnace has also proved to be very efficacious, so that it is at the present time considered the best apparatus for the concentration of sulphuric acid found in the trade.

The highest strength of sulphuric acid practically attainable by boiling down is 98 % H 2 SO, and this is only exceptionally reached, since it involves much expenditure of fuel, loss of acid and wear and tear of apparatus. The usual strength of the O.V. cf commerce, mostly designated by its specific gravity as 168 Twaddell, is from 93 to 95, or at most 96% HjSO^ When attempts are made to push the process beyond 98 % it is found that the acid which distils over is as strong as that which remains behind. Real " monohydrate " or acid approaching 100 % can be made by Lunge's process of cooling strong O.V. down to 16 C. when HjSOi crystallizes out, or by the addition of anhydrous SOs in the shape of fuming acid.

Since the development of the contact processes the fuming acid has become so cheap that it is now exclusively used for the preparation of the acids approaching the composition of " monohydrate."

Fuming or Nordhausen Oil of Vitriol, a mixture or chemical compound of HjSOi, with more or less SO 3 , has been made for centuries by exposing pyritic schist to the influence of atmospheric agents, collecting the solution of ferrous and ferric sulphate thus formed, boiling it down into a hard mass (" vitriolstein ") and heating this to a low red heat in small earthenware retorts. Since about 1800 this industry had been confined to the north-west of Bohemia, and it survived just till 1900, when it was entirely abandoned not because its product had become any less necessary, but, quite on the contrary, because the enormously increasing demand for fuming sulphuric acid, arising through the discovery of artificial alizarine and other coal-tar colours, could not possibly be supplied by the clumsy Bohemian process. Other sources of supply had accordingly to be sought, and they were found by going back to a reaction known since the first quarter of the 1qth century, when J. W. Dobereiner discovered the combination of SO 2 and O into SOs by means of spongy platinum. This reaction, now known by the name of the catalytic or contact process, was made the subject of a patent by Peregrine Phillips, in 1831, and was tried later in many ways, but had been always considered as useless for practical purposes until 1875, when it was simultaneously and independently taken up by Clemens Winkler in Freiberg, and by W. S. Squire and R. Messel in London. Both these inventors began in the same way, viz. by decomposing ordinary sulphuric acid by a high temperature into SO 2 , O, and H 2 O (the last of course being in the shape of steam), absorbing the water by sulphuric acid, and causing the SOj and O to combine to SOs by means of moderately heated platinum in a fin.e state of division. Winkler showed that this division was best obtained by soaking asbestos with a solution of platinum chloride and reducing the platinum to the metallic state, and he described later a specially active kind of " contact substance," prepared from platinum chloride at a low temperature. This revival of the synthetical production of SOs, at a period when this article had suddenly become of great importance, caused the greatest excitement among chemists and led to numerous attempts in the same direction, some of which were at once sufficiently successful to compete with the Bohemian process. It was soon found that the production of a mixture of SO 2 and O from sulphuric acid, as above described, was both too troublesome and costly, and after a number of experiments in other directions inventors went back to the use of ordinary burner-gas from pyrites and sulphur burners. For a good many years the further development of this industry was surrounded by great mystery, but it is now known that a satisfactory solution of the difficulties existing in the above respect was attained in several places, for instance, at Freiberg and in London, by the labours of the original inventors, Professor Winkler and Dr Messel. These difficulties were mostly caused by the solid impurities contained in the burner-gases in the shape of flue-dust, especially the arsenic, which after a short time rendered the contact substance inactive, in a manner not as yet entirely understood. Another difficulty arose from the fact that the reaction SO 2 -fO=SOa is reversible, the opposite reaction, SO 3 = SO 2 4O setting in but little above the temperature required for the synthesis of SOa- As far as is known (so much secrecy having been observed), the best results obtained in various places, save one, did not exceed 67 % of the theoretical quantity, the remaining 33% of SO 2 having to be converted into sulphuric acid in the ordinary lead chambers. As is now known, the exception (undoubtedly the only one until 1899) was the process discovered as early as 1889 by Dr R. T. J. Knietsch, of the Badische Anilin-und Soda-Fabrik, at Ludwigshafen, but kept strictly secret until 1899, when the patents were published. The principal features of this invention are, first, a much more thorough purification of the burner-gas than had been practised up to that time, both in a chemical and a mechanical sense, and second, the prevention of superheating of the contact substance, which lormerly always occurred by the heat generated in the process itself. As the Badische process effects this prevention by cooling the contact apparatus by means of the gaseous mixture to be later submitted to the catalytic action, the mixture is at the time heated up to the requisite temperature, and a considerable saving of fuel is the consequence. Altogether this process has been brought to such a pitch of simplicity and perfection, that it is cheap enough, not merely for the manufacture of fuming oil of vitriol of all strengths, but even for that of ordinary sulphuric acid of chamber-acid strength, while it is decidedly cheaper than the old process in the case of stronger acids, otherwise obtained by concentration by fire. It should be noted that these are not the results of a few years' working with an experimental plant, but of many years' work with large plant, now equal to a capacity of 120,000 tons of pyrites per annum. It is therefore not too much to say that, in all probability, the contact process will ultimately be employed generally for concentrated acids. Still, for the reasons given in the beginning of this article, the revolution thus impending will require a certain time for its accomplishment. Since the Badische process has become known several other new contact processes have come into the field, in some of which ferric oxide is employed as contact substance, but we must refrain from describing these in detail. (G. L.)

Medicine. Sulphuric acid or oil of vitriol is a colourless oilylooking liquid incompatible with alkalis and their carbonates, lead and calcium. There are two medicinal preparations: (i) Acidum sulphuricum dilutum, containing 13-65% of hydrogen sulphate, (2) acidum sulphuricum aromaticum (elixir of vitriol), containing alcohol, spirit of cinnamon and ginger and I3'8% of hydrogen sulphate.

Therapeutics For external use, sulphuric acid is a powerful irritant and caustic, acting by its powerful affinity for water and therefore dehydrating the tissues and causing them to turn black. It coagulates the albumen. Strong sulphuric acid is occasionally used as a caustic to venereal sores, warts and malignant growths. It is difficult, however, to limit its action, and glacial acetic and nitric acids are preferable for this purpose. Considerable burns on the face or body may result from the application of sulphuric acid in the practice known as " vitriol-throwing," a brownish black eschar serving to distinguish the burns produced by this acid from those of other corrosive fluids. Internally, dilute sulphuric acid is used in poisoning by alkalis as a neutralizing agent. Both it and the aromatic solution are powerful intestinal astringents, and are therefore useful in diarrhoea of a serious type, being strongly recommended both as a prophylactic and as a treatment during epidemics of Asiatic cholera. Small doses of the aromatic acid also serve as a prophylactic to those artisans who work in lead and as a treatment in lead poisoning in order to form an insoluble sulphate of lead. Sponging the body with very dilute solutions of sulphuric acid is useful to diminish the night-sweats of phthisis.

Toxicology. Given in toxic doses or in strong solution, sulphuric acid is a severe gastro-intestinal irritant, causing intense burning pain, extending from the mouth to the stomach, and vomiting of mucous and coffee-coloured material. The effects of the ingestion of large quantities may be so rapid that death may take place in a couple of hours, owing to collapse, consequent on perforation of the walls of the oesophagus or stomach, or from asphyxia due to swelling of the glottis consequent on some of the acid having entered the larynx. Should the patient survive the first twenty-four hours death generally results later from stricture of the oesophagus or intestine, from destruction of the glands of the stomach or from exhaustion. Death has occurred in a child from the ingestion of half a teaspoonful of the strong acid, but recovery is recorded after half an ounce had been swallowed. The treatment consists in the prompt neutralization of the acid, by chalk, magnesia, whiting, plaster, soap or any alkaline substance at hand ; emetics or the stomach pump should not be used. Morphine may be given hypodermically to mitigate the pain. Should the patient survive he will probably have to be fed by rectal enemata. The prognosis of sulphuric acid poisoning is bad, 60 to 70% of the cases proving fatal. The post-mortem appearances will be those of corrosive poisoning. The buccal mucous membrane will be greyish, brown " black in colour, due to the corrosive effects of the acid.

Note - this article incorporates content from Encyclopaedia Britannica, Eleventh Edition, (1910-1911)